The difference between dry extruder and wet extruder

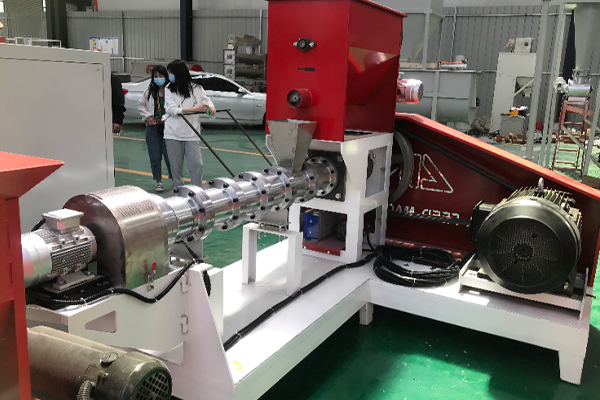

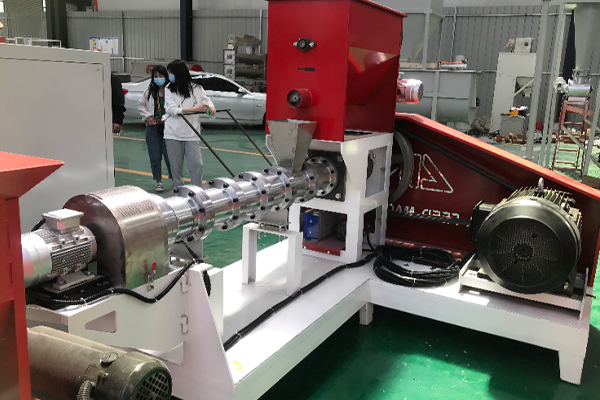

Dry extruder is an extruder without steam conditioner, and the raw materials are not pre-conditioned before entering the extrusion system.

Wet extruder is an extruder with steam conditioner, and the raw materials are pre-conditioned before entering the extrusion system. It can be seen from the definition that the most important difference between the wet and dry method is whether the material is pre-conditioned by steam before entering the extrusion.

Wet extruder is an extruder with steam conditioner, and the raw materials are pre-conditioned before entering the extrusion system. It can be seen from the definition that the most important difference between the wet and dry method is whether the material is pre-conditioned by steam before entering the extrusion.

Some people always understood the dry and wet method as the two working modes or methods of the extruder, rather than the essential difference in structure. From the working mode: according to whether the material is steam-conditioned before entering the extruder barrel (expansion cavity), it is divided into dry extruder and wet extruder. If it is steam quenched and tempered, it is a wet working mode; otherwise, it is a dry method.

Some people always understood the dry and wet method as the two working modes or methods of the extruder, rather than the essential difference in structure. From the working mode: according to whether the material is steam-conditioned before entering the extruder barrel (expansion cavity), it is divided into dry extruder and wet extruder. If it is steam quenched and tempered, it is a wet working mode; otherwise, it is a dry method.

The purpose of steam conditioning: increase the material temperature, soften and partially pre-cured materials, and add a certain amount of moisture. For most materials, wet expansion is more efficient than dry expansion.

A simple analysis is made by considering only the temperature factor. If the expected maturation temperature of the material is 130°C, the extrusion part of the dry expansion screw will increase from room temperature (20°C). To reach this value, the temperature needs to be increased by 110°C. If the wet method is used for production, the temperature after quenching and tempering is 80°C, and the material temperature that needs to be raised in the screw extrusion part is 50°C. Therefore, the mechanical energy required is less than that of the dry method and more energy Can be used to increase production. In addition, due to the softening of the material, the wear on the screw and barrel will also be reduced.

Many users, including some equipment vendors, literally think that adding water is the wet method. From the above brief analysis, we can know that simply adding water cannot be called a wet method. It only supplements part of the water, and it does not play the role of raising the material temperature, softening and partially pre-curing the material. Due to the different properties of the material entering the barrel during the dry and wet production conditions, the wet method enters the barrel is a hot and humid soft material, and the dry method enters the barrel is a cold and hard material. Therefore, the main shaft system and the extrusion screw The configuration requirements are also different.

Generally, the dry process machine with steam conditioning system can be used for wet production, and the efficiency will be improved, but it is not as efficient as the special wet process model; the impact of the hard material on the shaft system should be considered when the wet process model is dry. For some materials, dry production is possible, but the efficiency will be reduced, and it is not applicable to some materials. In other words, the dry process machine can be produced in the wet process, and the wet process machine may not be able to use the dry process